Flow range :3l/s to 300l/s

Lift range :30m~240m

Overcurrent material: HT200/304/316

Inlet and outlet diameter: 50mm~300mm

Speed: 1450/2900r/min

Contact Us

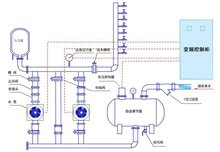

Non-negative pressure water supply unit, also known as superimposed water supply device, is mainly used for the secondary pressure of urban pipe networks and high-rise buildings.

The advantages:

Energy saving - superimposes the pressure of the original pipe network

Health - Water does not stay in the non-negative pressure tank will not deteriorate

Small size - one tenth of the footprint of traditional water supply

Automatic - the use of frequency conversion, timing, quantitative control can achieve unattended

Equipment working principle

(1) Frequency conversion constant pressure water supply: When the water supply of the municipal pipe network is greater than the water consumption of users, the constant flow tank type non-negative pressure water supply equipment frequency conversion constant pressure water supply, at this time, a certain amount of pressurized water is stored in the steady flow tank.

(2) Eliminate negative pressure: When the user's water consumption increases, the pressure at the connection between the municipal pipe network and the stabilizing tank will drop. The valve opens and atmospheric air enters the surge tank. At this time, the steady flow tank is equivalent to an open water tank with a free liquid surface, the pressure is the same as the atmosphere, and the negative pressure is eliminated. When the water level drops to the set value, the liquid level controller transmits the control signal to the control system in the frequency conversion control cabinet to control the pressurization unit to stop working, and the user stops the water; when the user's water consumption decreases, the water level in the steady flow tank rises, The gas is discharged from the exhaust valve of the vacuum suppressor. After the pressure returns to normal, the pressurization unit restarts automatically to restore the water supply.

(3) Water stop function: When the municipal pipe network stops water, the pressurization unit will automatically stop running under the control of the liquid level controller. After the municipal pipe network water supply is restored, it will automatically start and resume normal water supply.

(4) Small flow sleep function: when the user does not use water or the water consumption is very small, the device automatically enters the sleep state (shutdown) and maintains the water supply pressure. When the user resumes water use, the system automatically wakes up and restores normal water supply.

(5) Continuous water supply in case of power outage: When the community has a power outage, the municipal pipe network will continue to use water supply to the low area, and the power outage will not stop the water supply. After the power supply of the equipment is restored, it will automatically start and resume normal water supply.

Installation Notes

1. The equipment should be installed on a foundation with a strength not lower than C20 and drainage facilities and maintenance channels should be left around;

2. The installation location of the equipment should be selected in a relatively dry environment, avoiding the open air environment, so as to avoid damage to electrical components;

3. Before installation, carefully check whether there are hard objects in the pump body, so as not to damage the impeller and pump body during operation;

4. The pipeline is not allowed to be added to the pump during installation, so as not to deform the pump and affect the normal operation;

5. Connect in sequence according to the installation drawings, the joints are sealed, and no forced installation is allowed. When the main pipe has a large diameter, it needs to be supported to avoid stress;

6. Tighten the anchor bolts so as not to affect the performance of the pump due to vibration during startup;

7. Install a regulating valve on the inlet and outlet pipelines of the pump, and install a pressure gauge near the pump outlet to control the pump to operate within the rated working condition and ensure the normal use of the pump;

8. The test pressure of the piping system is 1.5 times the rated pressure and kept for more than 5 minutes. During the pressure test, the piping system must not have any cracks, dripping, leaking or seepage;

9. If the discharge pipeline is equipped with a check valve, it should be installed outside the gate valve;

10. The installation method of the pump is divided into rigid connection installation and flexible connection installation.

Product range

Building pressurization, urban water supply, water plant pressurization, medicine and food

Customized and reliable:

According to the actual situation of each pumping station and local conditions, we provide users with targeted and systematic pumping station solutions to ensure water supply, reduce investment and operating costs, and facilitate maintenance.

Do you always have pumps in stock ?

We do have some models pump in stock. However, most of the pumps need to be placed an order to produce them for you. Since, there are hundreds of models in our product catalog, its really very hard for us to have all of them in stock.

How long will it take for you to customize a pump for me ?

It will take 30~45 days to design the pump and open the pump mold. Time cost depends on the pump’s power, size ,performance, special function etc.

Do you accept payment made by Paypal ?

Yes, we do accept payment made by Paypal and prefer sample fee and small order make by Paypal. That will save much transfer time than T/T payment.

What’s the freight channel do you use for delivering the goods?

We usually use express such as DHL, FedEx, UPS, air ways to deliver samples and small quantity orders. For bulk orders we recommend customers ship the goods by sea so as to save freight fee.

You will attend the fair to show your products?

Yes, we will attend the international fair to show our products,Such as China Canton Fair,And other fairs around the world.

Does Ruichen Pump supply pumps that comply with API 610 standards?

Yes, Ruichen pump do supply pumps complying with API 610 standards.

Which kind of data are necessary in order to select the right pump?

When you work with chemicals and dangerous liquids, it’s fundamental to select the right pump suitable for the customer’s application and required performances. Ruichen Pump experienced personnel carefully evaluates the customer’s needs, paying attention to all the technical data. In particular, the following data are the most important in order to choose the right pump: capacity/flow and head/pressure required, kind of liquid, concentration, temperature, viscosity, possible presence of solids in suspension and if known also NPSHa.

Which is the best material for a pump?

When you talk about pumps for acids the choice of the material depends on different aspects. Our high-skilled personnel can help you in this evaluation by collecting some data about the kind of corrosive liquid you have to pump, the concentration and temperature. Our chemical compatibility charts, created according to our decennial experience, are very useful in these cases, but it’s necessary to perform a deep analysis of the final application and of the required performances in order to select the correct chemical pump model. Our technicians are always available to select the correct pump and the best material for the customer’s application.

Does Ruichen Pump supply also customized pumps?

Yes, Ruichen Pump supplies many different pumps for acids and dangerous liquids series with more than 400 variations, giving the customer the opportunity to customize the pump according to his needs.

Our wide range of products includes:

– different kind of pumps suitable for pumping corrosive and dangerous liquids: mag drive centrifugal pumps, mag drive turbine pumps, mag drive rotary vane pumps, mechanical seal pumps, liquid ring vacuum pumps, vertical pumps, ATEX pumps and portable pumps;

– 3 different pump materials resistant to chemicals: pumps in PP (polypropylene), pumps in PVDF (polyvinylidene fluoride) and pumps in AISI316 ;

– different kind of o-rings compatible with most of the existing chemicals;

– many accessories for chemical pumps, including dry running protection devices, flanges and baseplates.

Upon request, Ruichen pump can evaluate new projects for the design and production of special customized pumps.

How can i to be your agent in my country?

You need do a market research report of your country of our productsAnd need to promise us how much amount you can finishThen we can check and sign a contract of the dealer or the agent.

What’s the main products of Ruichen Pump?

Ruichen Pump manufacture almost all kinds of pumps, High-Speed Centrifugal Pump including GSB 311,GSB 322 and GSB 341. Also with Civil pumps including water pump and fire pump. We are production for over 10 years with high performance and quality as well as competitive price.

Which certificate you have to your pumps?

We have ISO900 and CE certificate.

Where is your factory located? How far is your factory from the airport?

We are the factory that located at JiaXing City, Zhejiang Province.

It will be about 1 hour from the airport to our factory

When you will provide the designing options for us?

We will arrange your designing after all requirements done, Then Check with our designers and will provide to you within 2 weeks.

What’s your production time(lead time)?

We can delivery the goods after we received your payment as long as we have the products in stock. Small order production time is about 30 days,. Complete set of pump, the bulk order production time is 2-3 months.

Max Flow 150M³/H

Max Head 1920 m

Max Suction Pressure 6.8MPa

Max Operating Pressure 20.0MPa

Max Motor Power 132kW

Operating Temperature -130~+340°C

RPM 4950-23700

Gearbox Construction Form Second-Level Growth Speed

Max Flow 52M³/H

Max Head 915 m

Max Suction Pressure 4.0MPa

Max Operating Pressure 10.0MPa

Max Motor Power 37kW

Operating Temperature -130~+340°C

RPM 4900-14179

Gearbox Construction Form First-Level Growth Speed

Max Flow 250M³/H

Max Head 2180 m

Max Suction Pressure 6.8MPa

Max Operating Pressure 20.0MPa

Max Motor Power 355kW

Operating Temperature -130~+340°C

RPM 4950-28000

Gearbox Construction Form Second-Level Growth Speed